TAC CNX 1UF

Description and processes

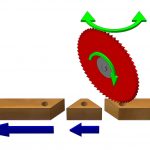

NC CUTTING AND DRILLING WORKING CENTER with cutting blade and vertical drilling unit. Automatic loader with magazine.

TAC CNX 1UF is the ideal solution for automatic processing of angular cutting and vertical drilling from long bars of solid wood elements, mdf, chipboard, multilayer, etc..

It finds its optimal use in the processing of elements for chairs, furniture, sofas, packaging, stairs, wooden floors, decking, fine arts items, and various applications.

Strengths

Automatic bar machining and controlled NC feed step by step of the loader allow continuous production. The large-diameter circular saw blade allows to process elements even of considerable section, with cutting angle from +60° to -60°. The cutting angle is controlled by NC, thus allowing infinite combinations of angle on the same bar at work.

The drilling operation (single or multiple) is automatically managed by NC.

The particular loading system, without pusher but with double self-centering gripper, allows to obtain extremely precise tolerances and clean and accurate cuts, even on elements with delicate surface.

Easy programming thanks to the touch-screen NC panel.

Advantages

- High quality mechanics

- Continuous cycle productivity

- Fast and accurate set-ups

- One operator per loading/unloading

- Efficient cleaning with dust containment and waste collection

- Simple and intuitive programming with dedicated software

- Wide customization

- Proven technology for industrial use, even on multiple shifts

Request

information

Contact us for any information, clarification and specification on our products and services.

T. +39 0432 740319

info@camamsrl.it